Create sanitary washdown zones fast. These food-grade curtains use non-porous PVC with stainless steel tube track to shed debris, speed sanitation, and reduce downtime.

• Non-porous, “slick” PVC surface for easy cleaning

• Heat-sealed hems (no stitching) to avoid debris harborage

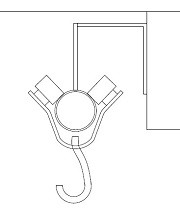

• Stainless steel tubular track with rounded carriers

• Clear and opaque color options

• Configure any layout; add radius corners and wall mounts

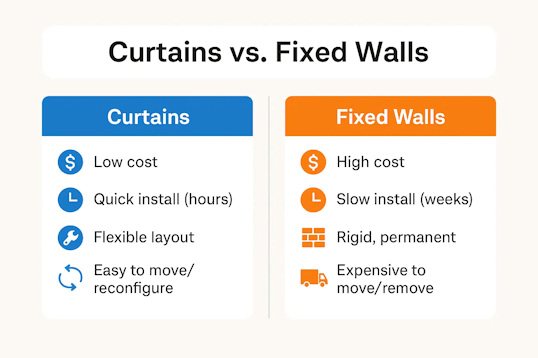

Designed For Speed and Flexibility

Key Benefits

- Food-safe construction for faster sanitising: Non-porous PVC with heat-sealed hems minimizes harborage points and wipes clean quickly.

- Debris-shedding stainless tube track for cleaner hardware: Rounded carriers and radii prevent buildup, ideal for food wash-downs equipment.

- Targeted containment for less overspray: Curtains confine water and sanitiser to the wash zone, protecting adjacent lines and staff.

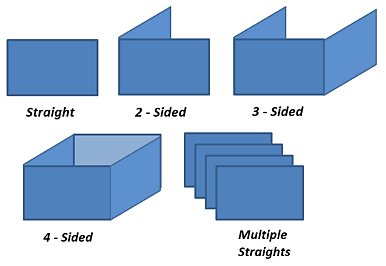

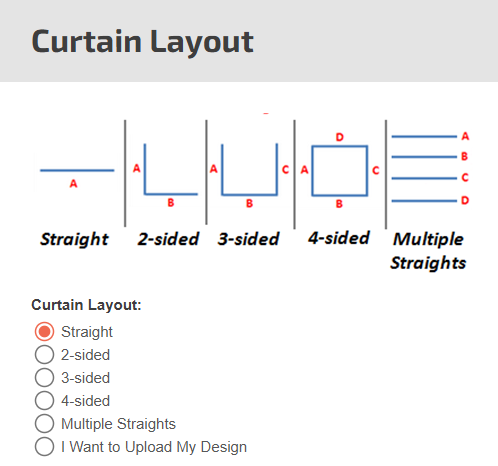

- Modular layouts to fit any footprint: Single, double, triple, four-sided, or multi-straight with radius corners; easily reconfigured as needs change.

Keep the Spray at Bay

Easy Install

The curtain walls come with grommets at the top, making hanging these contamination curtains quick and easy. Minimal tools are required.

Food-Safe Materials

Non-porous PVC with heat-sealed hems. Hygienic wash-down curtains can be cleaned quickly between washdowns.

Sanitary Barrier

Forms a durable physical barrier in any layout, with stainless tube track and radius corners for a debris-shedding design.

Controls Overspray

Confine wash water and sanitiser to the zone to protect adjacent lines, equipment, and bystanders.

Slick, Seamless, and Sanitary Curtain Solutions

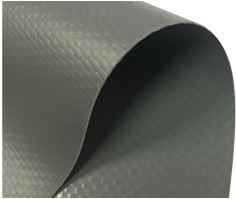

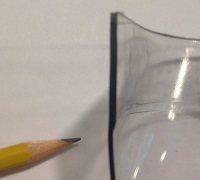

Slick Surface

The materials are specifically designed to be “slick” which will shed solutions and soils, unlike porous materials.

No Stitching

There is no stitching which is commonly used for the hems. A stitched hem can allow debris to get under the fold which leads to bacteria growth.

Form Any Shape

The curtains have the ability for any shape. This allows the food safe curtain to be moved seamlessly around equipment.

Waterproof Material

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

Available in Multiple Colours

Strong Material That Lasts

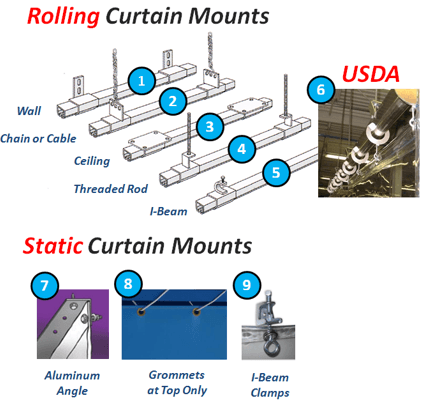

Easy Rolling Curtain Track

- Smooth Glide – Curtains roll open and close with ease.

- Durable Track – Heavy-duty steel for long-lasting use.

- Flexible Mounting – Ceiling, wall, or chain-hung options.

- Quick Setup – Fast installation, minimal tools needed.

- Low Maintenance – Reliable performance with little upkeep.

Ideal Applications for Wash Down Curtains

Food Processing Curtains

- Design for sanitation flow: Layouts follow equipment, drains, and access paths so crews clean efficiently without soaking the room.

- Proven in food wash down: Heat-sealed seams, stainless grommets, and sanitary trolleys support repeatable clean-in-place routines.

- Outcome: Increased line efficiency and reduced changeover downtime with reliable separation between equipment.

Brewery Sanitation Curtains

- Splash containment: Separate kettles and fermentation vessels to catch splashes during transfers.

- Post-brew wash down: Confine rinse water and chemicals to the work zone for cleaner aisles and faster turnarounds.

- Outcome: A sanitary divider that keeps brewing spaces tidy while improving safety for staff and bystanders.

Hygienic Curtain Benefits

- Greatly improves plant sanitation

- Prevents cross-contamination between equipment

- Specially designed trolley eliminates the collection of debris

- Water that is sprayed onto equipment is confined to that area

- Hygienic wash down curtains allow for just the area around the equipment to be cleaned

- Eliminates expensive downtime

Meets Required Code

Title 21 CFR Approved

The USDA passed the onus of compound compliance/approval to be under FDA provisions, specifically Title 21 CFR (Code of Federal Regulations). Since the USDA does not approve equipment or materials, we have material that meets CFR 21, which ensures that the compounds used are FDA certified raw materials. The AKON curtains are Title 21 CFR compliant and carry a UFL-94 Fire Cert.

CFIA Approved

In addition to meeting USDA standards, the curtains also meet Canadian Food Inspection Agency or CFIA approval. The CFIA is much like the USDA in the United States. Their purpose is to ensure the health and safety of food and food production. Our curtain material has been sent to the CFIA for a full review and it now has their seal of approval.

Steel Hardware

Stainless Steel Mounting Hardware

Our food safe curtain hardware is designed with a stainless steel tubular track system featuring rounded corner carriers. This smooth, sanitary design prevents water and debris buildup, allowing easy washdown and reducing bacteria risk, unlike traditional C-channel curtain hardware that can trap contaminants.

Side Wall Mounting Options

For facilities where overhead track mounting is not possible, our side wall mount attachments provide a secure and sanitary solution. This hardware mounts directly to vertical walls, making it ideal for food processing plants, dairies, and washdown areas with overhead obstructions.

Radius Corners for Custom Layouts

We manufacture radius corners in standard 60 cm and 30 cm 90° bends, with the ability to create nearly any radius required for your facility layout. Mounting tabs can be supplied welded in place or shipped loose for flexible installation.

Heavy-Duty Stainless Steel Grommets

Our curtains use stainless steel grommets every 30 cm along the reinforced edge double-folded top hem for maximum strength. Additional grommets can be added to vertical edges for secure and sanitary hanging in high-use environments.

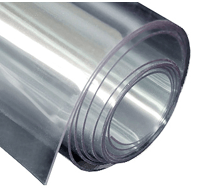

40 Mil Clear PVC Curtains

Made from 40 Mil Clear Vinyl PVC, these washdown clean curtains are approved for incidental contact with meat, poultry, and dairy products. They are durable, flexible, and meet strict federal compliance standards.

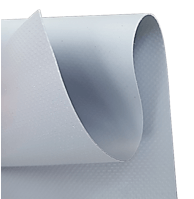

18 oz Opaque White Curtains

When visibility control is needed, we offer 18 oz opaque white vinyl curtains. These curtains are also designed for heavy washdown use while maintaining full privacy in processing areas.

How to Order

- Use our Build Online Tool to customise size, colour, and options.

- Request a free quote with guaranteed response within 24 hours.

- Fast lead times and worldwide shipping available

Photo Gallery

40 Mil Clear

- 40 mil USDA Grade Flexible PVC - Non-Porous

- Grommets every 12" located at the top of the curtain - Stainless Steel

- Grommet hem is double thick for additional strength

- Hems are heat sealed to prevent bacteria growth

- Colors: Clear only

- Double polished

- Operating temperature: -28°C to 60°C

- Made for safe contact with food

- Fire retardant

- CFIA Certified

- Title 21, SI 5113 Certified

18 Oz White

- 18 oz USDA Grade Flexible Vinyl

- Grommets every 30cm located at the top of the curtain - Stainless Steel

- Grommet hem is double thick for additional strength

- Hems are heat sealed to prevent bacteria growth

- Colors: White

- Operating temperature: -48°C F to 70°C

- Made for safe contact with food

- Fire retardant

- CFIA certified

- Title 21, SI 5113 certified

- For this material please use our custom quote form