Prep Station Curtains are a durable, flexible, and cost-effective solution for automotive shops and industrial facilities. Easily contain overspray, dust, and wash-down water while keeping your workspace safe and organised.

- Contain paint overspray, sparks, and dust.

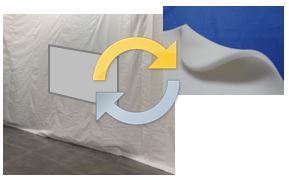

- Easy roll-away and reconfigure

-

Fire-code compliant, 5-year warranty

Designed For Speed and Flexibility

Key Benefits

-

Contain sparks, overspray, aluminum & steel dust

-

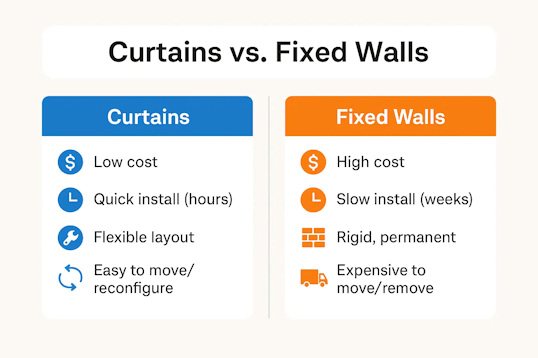

Reduce setup cost, about 1/3 the price of rigid walls

-

Easy installation, quick reconfiguration

-

Easy cleaning, mildew-resistant vinyl

-

Fire-retardant and safety compliant

-

Modular system grows with your shop

Keep the Spray at Bay

Easy Install

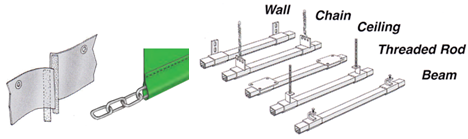

Prep station curtains come with grommets at the top making hanging the curtains quick and easy with or without the curtain track.

Inexpensive

Prep station curtains are about 1/3rd of the cost of other separation methods such as rigid walls or panel systems and are easy to store.

Separate Workers

Prep station curtain walls are ideal for separating workers for welding, washing, packaging and many other operations.

Control Noise

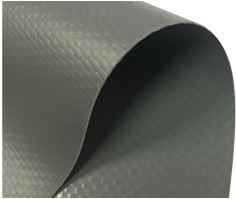

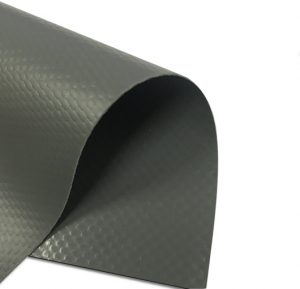

Prep station curtains help reduce noise due to the thick PVC they are made from which makes for a more comfortable work environment.

Waterproof Material

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

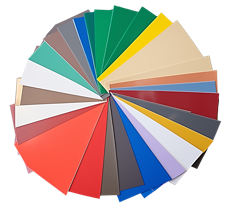

Available in Multiple Colours

Strong Material That Lasts

Easy Rolling Curtain Track

- Smooth Glide – Curtains roll open and close with ease.

- Durable Track – Heavy-duty steel for long-lasting use.

- Flexible Mounting – Ceiling, wall, or chain-hung options.

- Quick Setup – Fast installation, minimal tools needed.

- Low Maintenance – Reliable performance with little upkeep.

Multiple Sizing Options

-

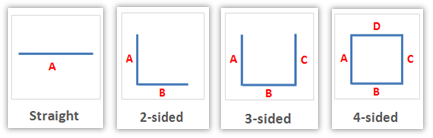

Single-, double-, triple-, or four-sided enclosures

-

Custom colours available

-

Optional clear vision panels

-

Chain-weighted hems for stability

Choose A Style

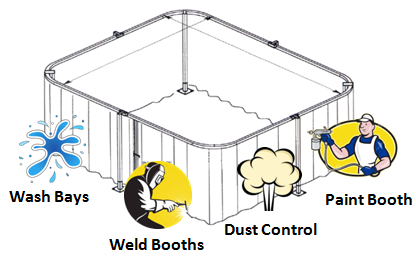

Ideal Applications for Prep Station Curtains

- Paint prep station curtains

- Prep booth curtains

- Retractable paint booths

- Detailing Wash Bays

- Under Coat Bays

- Grinding and Sanding Bays

- Under Coating Curtains

Designed For Speed and Flexibility

Common Layouts

Paint spray booth curtains can be configured in multiple layouts depending on your workspace needs. Options include:

- Single-sided for partitioning one wall

- Double-sided for dividing larger bays

- Three-sided to create partial enclosures

- Four-sided for complete booth enclosures

Simply tell AKON your preferred layout, and we’ll fabricate it to your exact specifications.

Optional Components

- Floor anchors to secure the prep curtains to the floor

- Many custom colors to choose from to match your facility

- Clear vision panels allow line of sight through the curtains

- Chain weight pocket ensures prep curtain will not blow around

Easy Installation

Installing spray booth curtains is fast and straightforward:

-

Unbox and assemble the modular track hardware.

-

Insert the roller hooks into the track.

-

Hang the curtains using grommets at the top edge.

Your booth can be up and running in hours - not weeks - minimising downtime. Once the curtains arrive, simply unbox them and follow our simple directions.

Filter Panels for Ventilation

Curtains can be fitted with replaceable filter panels (10cm x 10cm or 10cm x 5cm). These allow negative pressure inside the enclosure, working with ventilation systems to control fumes and overspray. Filters attach with Velcro and can be replaced when clogged.

Aluminum Dust Containment

Modern auto body shops require enclosed work zones for aluminum dust management. Our aluminum repair enclosure curtains create fully sealed areas for grinding and sanding, ensuring compliance with safety requirements and preventing contamination of other bays.

Maintaining The Curtains

The vinyl material is smooth and easy to clean, much like a shower curtain.

-

Wipe down dust and overspray with a cloth.

-

Wash with mild soap and water for heavier buildup.

-

Mildew-resistant and chemical-resistant properties ensure long life.

-

Clear repair tape is available if a curtain becomes torn.

Common Questions About Prep Station Curtains

What are prep station curtains and how do they work?

Prep station curtains are heavy-duty vinyl partitions that slide on a ceiling- or wall-mounted track to create a contained work area for sanding, washing, and paint prep. They help control overspray, dust, and water while keeping adjacent areas clean and productive.

Do the curtains meet fire-retardant and safety requirements?

Yes—fire-retardant curtain materials are available and supplied with compliance documentation on request. Hardware is heavy-duty steel and designed for industrial use. If your facility requires a specific certification, we can match the material accordingly.

How do I clean and maintain prep station curtains?

Wipe down with mild soap and water or approved cleaning agents. For heavier debris, rinse and allow to air dry. Periodically check grommets, hems, and rollers; replace worn parts to maintain smooth operation.

What sizes and customization options are available?

Systems are built to order. Choose single, double, three-sided, or four-sided layouts; clear vision panels; colours; valances for floor-to-ceiling coverage; and chain-weighted hems. Track can be ceiling-mounted or free-standing to suit your bay layout.

Can I add filter panels or replace them later?

Yes—filter panel windows can be integrated into the curtain and attached with hook-and-loop for easy removal and replacement when they become clogged or airflow needs change.

Is installation difficult? What does it include?

Installation is straightforward: bolt together the modular steel track, anchor per the mounting surface, and hang the curtain via grommets and rollers. Most shops complete a bay in hours, not weeks. Layout guidance and hardware are included with each order.