Create mobile, food-grade barriers that stop overspray and cross-contamination without blocking workflows or requiring overhead structure. Roll into place for washdown, then store away when not needed. Prevents Cross Contamination in Food Processing Plants .

-

Mobile USDA Grade Curtains containment where overhead mounting isn’t possible

-

40 mil non-porous PVC shade with heat-welded hems; stainless grommets

-

Bolt-together stainless frame; bead-blast finish; welded/capped corners

-

Smooth mobility on 3″ swivel casters; optional metal-detectable zip ties

-

Optional walk-through version with roller-hook track (no need to move the frame)

-

5-year warranty on manufactured defects (curtains & shade)

Designed For Speed and Flexibility

Key Benefits

- Fast, flexible containment: Deploy only when and where needed; roll away after washdown to free floor space.

- Food-safe by design: 40 mil USDA-grade, non-porous PVC shade with heat-welded hems helps prevent bacterial growth from overspray. Meets Title 21 CFR.

- Built to last: Stainless frame with bead-blast finish, welded/capped corners, reinforced legs, and 3″ swivel casters.

- Walk-through access: Roller-hook track lets staff roll the curtain open to pass people or materials without moving the screen. Ideal when screens stay in place.

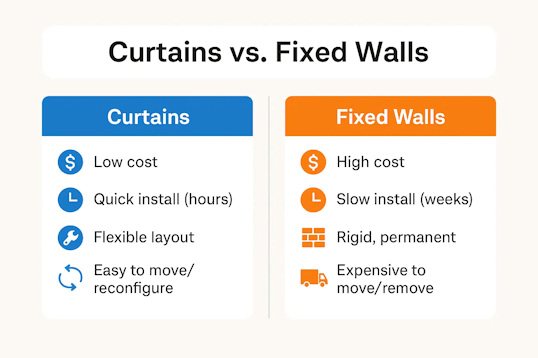

- Lower cost & downtime than walls: Get containment without construction or facility shutdowns (budget pricing shown below)

Specifications

| Feature | Details |

|---|---|

| Warranty | 5-year on manufacturing defects. Coverage applies to manufacturing defects only. |

| Frame | USDA-grade stainless; bolt-together; bead-blast finish. |

| Mobility | 3″ swivel casters; screen bottom ~5″ above floor with casters. Clearance measured with casters installed. |

| Legs | 24″–36″ mounting legs; 1/4″ reinforcement plates. |

| Floor interface | Optional oversized screen to rest on floor. |

| Fasteners | Standard zip ties; optional metal-detectable zip ties. |

| Shade | 40 mil USDA-grade flexible PVC; non-porous; heat-welded hems; stainless grommets; meets Title 21 CFR. Compliant materials suitable for food-contact environments. |

| Access option | Walk-through version with roller-hook track. |

Materials

40 mil USDA-grade flexible PVC that is non-porous with heat-welded hems and stainless grommets to minimize debris traps; meets Title 21 CFR.

Frame System

Bolt-together USDA-grade stainless with a bead-blast finish, welded/capped corners, reinforced legs, and 3″ casters for smooth mobility; ~5″ floor clearance (oversized shade option to rest on floor).

Sizes & Customisation

Choose static or walk-through; set your width/height and leg widths; add metal-detectable ties or oversized floor-rest shade.

Walk Through Portable Wash Down Screens

When you need a portable food processing wash down shield but also want to have access to walk through it rather than moving it then you can utilize the walk through version. This model utilizes our curtain track with roller hook design which allow you to roll the curtains back. This allows the associate to walk through or move material through the frame. These are ideal when you plan on leaving the Portable USDA Wash Down Screens in place with no need to move them that often.

Build Yours Online

Budget Price

Size: 10′w x 10′h

Static Shade Style: €4,400

Roller Hook Shade Style: €5,200

Frequently Ask Questions About Portable USDA Wash Screens

What are portable USDA wash down screens?

They’re mobile, food-plant screens you can roll to the washdown area when needed and store away when not in use. They help prevent cross-contamination by confining overspray and debris during cleaning around equipment and process lines.

When would I choose these over hanging USDA curtains?

Use portable screens where overhead mounting isn’t possible. They deliver the same containment benefits as suspended USDA curtains but add fast setup, mobility, and easy storage between tasks.

How are the frames constructed?

The frame is bolt-together USDA-grade stainless steel with a bead-blast finish. Corners are welded shut or capped to prevent contamination, with 24–36" wide mounting legs (1/4" reinforcement plates) and 3" diameter swivel casters for smooth movement.

What is the curtain ("shade") material?

A non-porous 40 mil USDA-grade clear PVC with heat-welded hems (no stitching) and stainless grommets. It’s designed specifically for food processing environments that require frequent washdowns.

Is the material compliant for use near food?

Yes. The clear PVC meets FDA Title 21 CFR requirements for incidental contact and is engineered to resist bacterial harborage from overspray in sanitation areas.

How mobile and fast to deploy are they?

The stainless frame and industrial casters make the screens easy to roll into place. The bolt-together design supports quick installation and rapid reconfiguration as needs change.

Is there a walk-through version?

Yes. A walk-through model uses curtain track with roller hooks, so you can roll the shade back to pass personnel or materials through without moving the frame—ideal when the screen will remain in position.

What about floor clearance and containment?

The bottom of the screen sits about 5" above the floor when on casters. An oversized shade option can be specified to rest on the floor for added containment.

How do I size and order one?

Use the online builder to choose dimensions and shade style (static or roller-hook). You’ll receive a budget price and configuration tailored to your layout.

What’s the warranty and available accessories?

There’s a 5-year warranty on manufacturing defects. Standard zip ties are included, with optional metal-detectable ties for food-plant protocols.