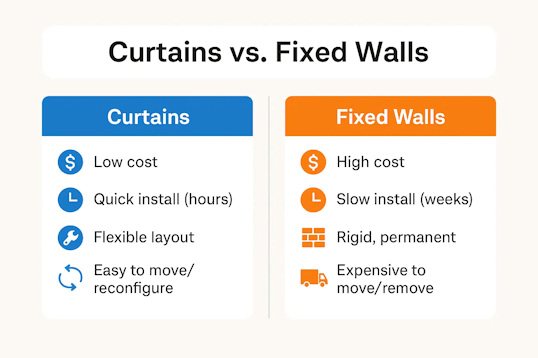

When fixed walls are costly and slow to build, temperature separating curtain walls deliver fast, flexible climate zones for warehouses and production floors, at roughly a third of the cost of rigid walls and with much quicker installs. These modular insulated panels reconfigure or come down when layouts change.

- Create temperature & humidity zones to save energy and improve comfort.

- Modular, reconfigurable panels, take down or move as needs evolve.

- Faster install than rigid construction; often about 1/3 the cost.

- Designed for warehouses, distribution, and manufacturing environments.

Designed For Speed and Flexibility

Key Benifits

- Lower energy loss: Insulated batting between reinforced vinyl skins helps maintain different temps across zones.

- Better processes: Effective for product storage and manufacturing lines needing controlled RH.

- Minimal downtime: Panels ship ready to hang; installation is straightforward vs. construction.

- Future-proof: Soft walls can be removed or relocated as operations change.

- Keep traffic flowing: Add magnet/Velcro splits or door options for quick movement through zones.

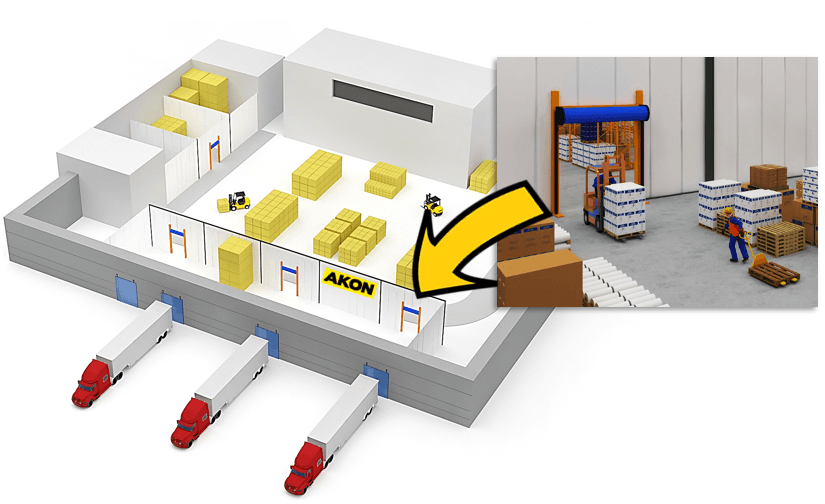

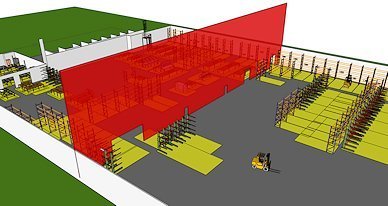

Section Warehouse Space Quickly

Temperature Zoning

Create temperature zones for storing products at different temperatures or to create a more comfortable work environment.

Humidity Control

Effectively control humidity levels within your facility for food products or for better manufacturing processes.

Separate Tenants

Zone or lease out your warehouse to tenants who need to be kept separated due to their different operations.

Control Noise

Insulated curtains are also dual purpose noise control curtains due to the thick batting they are made from.

Applications for Insulated Warhouse Curtains

- Temperature zoning for storage & staging

- Process isolation (packaging, assembly, QC)

- Tenant separation in shared warehouses

- Humidity control for sensitive goods

- Seasonal partitioning near docks and canopies

Temperature and Humidity Zoning

Temperature Benefits

- Create temperature zones for employee comfort

- Create temperature zones for food products or materials

- Easy to install behind your loading dock to save heat/cold loss

- Keeps consistent temperatures in various zones to save energy

Humidity Benefits

- Ideal for food distribution plants to preserve quality of food

- Increases comfort for employees

- Curtain walls have Vinyl skins which contain condensation

- They have anti-microbial agent to prevent mold or mildew

- Allows chilling equipment to operate using less energy

Tenants and Work Zones

Manage and Zone Work Flow

- Allows you to design and redesign temperature spaces

- If storage needs change, the walls can be easily moved

- Make spaces larger or smaller with modular 1.5m wide panels

- If not needed, the entire wall can be stored in pallet boxes

- Unlike fixed walls no demolition is needed for redesign of layout

Manage and Zone Tenants

- Keeps warehouse lease tenants zones and separated

- Warehouse insulated curtains are ideal for temporary tenants

- If you lease out your warehouse, the curtains can divide work space

- They are also ideal at creating work areas for designated products

- After the lease is over the curtain walls can be taken down and stored

- The soft curtain walls can also be reconfigured for future lease tenants

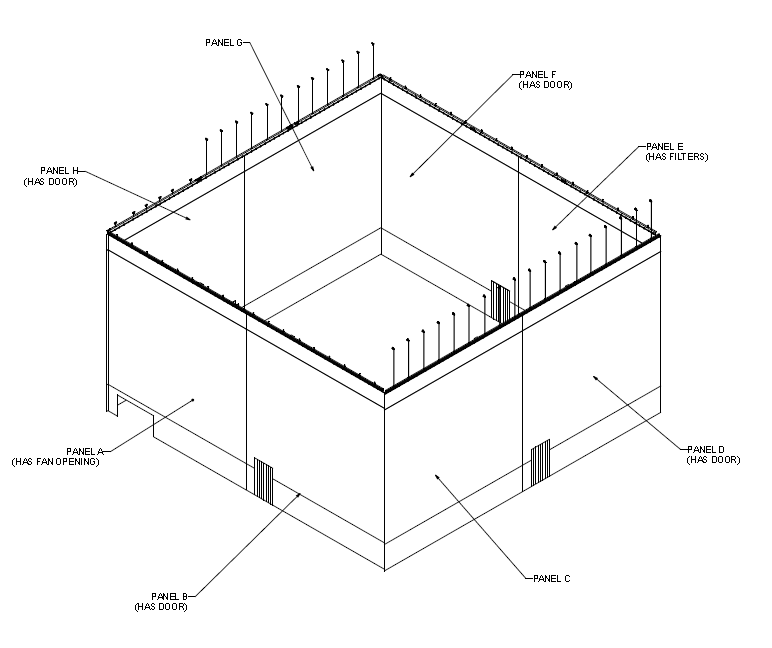

Construction and R-Values

Construction

The industrial insulated curtains have a thermal batting inside of two outer layers of reinforced Vinyl. The material is fire retardant to meet requirements set forth by most local and state regulations. Batting thickness depends on your required warehouse temperature separating needs.

R-Values

AKON insulated curtains can provide temperature separation up to 22°C. The thicker the batting, the higher the R-value you will achieve. We help you determine which R-value to choose based on your desired temperature zones and the duration you will need to use the insulated warehouse dividers. For instance, if your needs are short-term, it is best to choose a lower R-value to reduce your expenses.

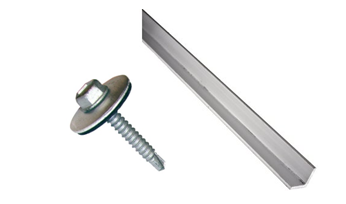

Quick Installation

Installing The Curtains

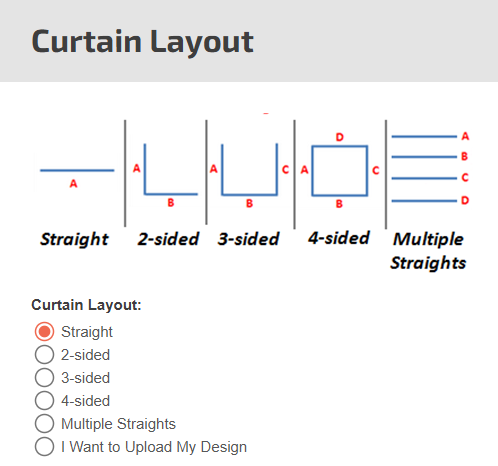

The curtains come in 1.5 meter wide panels that Velcro together from top to bottom. Once connected, they form walls that can be in almost any configuration. They run from the roof deck to the floor or from the bottom of the joists to the floor. Aluminum angle is the most common mounting method, as it quickly attaches to the roof deck. You simply connect the angle to the structure and then use Tek screws with washers to pinch the curtain panels every 30cm to the angle. Need an installer? Ask AKON for one of our national installers to install your wall.

Seals Around Obstructions

Most curtain installations run all the way to the roof deck for a complete environmental seal and separation of environments. It is not uncommon with this type of installation to have to cut around purlins, joists, conduit, and other obstructions. The curtains are made to be field cut, and AKON provides special field patch tape to seal them back together at the split. It is very quick and very cost-effective.

Entry and Exit Options

Entry Options

Insulated warehouse dividers are static position curtains. That means they do not roll side to side to allow people or material in. Rather, the curtains feature entry and exit locations. The most common types of entries and exits include strip curtains, swinging doors, and powered roll-up doors. Strip doors are the most common and economical. Each version features a freestanding frame that anchors into the floor and seals to the curtain wall.

Your Design Becomes Reality

From Design to Installation

AKON is the industry leader in warehouse separation curtains. Our company can take your design from concept to shipping in only 10 working days. We work closely with industrial engineers and small business owners to bring their objectives to life.

How to Order

- Use our Build Online Tool to customise size, colour, and options.

- Request a free quote with guaranteed response within 24 hours.

- Fast lead times and worldwide shipping available

Common Questions about Insulated Warehouse Curtains

How much temperature separation can I expect?

Actual performance depends on layout, sealing, and traffic. With proper configuration, insulated curtain walls deliver meaningful climate control for warehouse zones.

Are these walls reconfigurable if our layout changes?

Yes. Panels are modular “soft walls” that can be taken down, moved, extended, or reinstalled as operations evolve.

How do they compare to building rigid walls?

Curtain walls typically install faster and cost significantly less than fixed construction while preserving future flexibility.

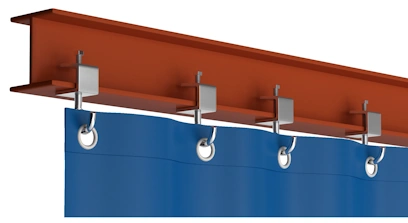

What mounting options are available?

Ceiling, wall-face, or suspended curtain track with roller hardware. We match the mount to your structure and clearances.

Can I add doors or quick access points?

Yes—integrate strip doors, swinging impact doors, powered roll-ups, or magnet/Velcro access splits to keep traffic flowing.

Do they help with humidity control as well as temperature?

Yes. Insulated panels and appropriate sealing help manage temperature and humidity for storage and process areas.

What are the panels made of?

Reinforced vinyl outer skins with an insulated batting core. Fire-retardant options and clear vision panels are available.

What sizes can you make?

Everything is made-to-measure—from short spans to long multi-straight runs and four-sided enclosures for large zones.

How do you seal the edges and the floor?

Use side-wall Velcro/magnets, overlapping panels, and optional floor sweeps or anchors to reduce air exchange at gaps.

Photo Gallery

R-Values

- R3 - 8°C of temperature separation

- R6 - 14°C of temperature separation

- R9 - 19°C of temperature separation

- R15 -22°C of temperature separation

Weight | Thickness

- R3 - 2.00 kg/m² | 15.24 mm

- R6 - 2.34 kg/m² | 25.4 mm

- R9 - 4.00 kg/m² | 106.68 mm (76.2 mm air gap)

- R15 - 4.69 kg/m² | 127 mm (76.2 mm air gap)

Fire Codes

- Fire retardant: Exterior and interior ASTM E84 Class A Rating

Specifications

- 1.5m wide panels

- Full length industrial grade Velcro on panels for connecting

- Grommets on 30cm centers at top of each panel

- Temperature range: −28 °C to 71 °C

- Skins: 19 oz acrylic coated vinyl exterior vinyl

- Batting: Double batting antimicrobial core

- 15cm floor sweep to engage floor