OVERVIEW

Food-grade PVC strip curtains and doors are manufactured from hygienic compounds suitable for areas where incidental contact with meat, poultry, dairy and other food products may occur. They are designed for use in food processing and cold-storage environments across Europe and the UK, supporting compliance with EU and UK food-hygiene legislation and HACCP-based standards in modern food production facilities.

Quick Entry & Exit

Quick Access Without Opening

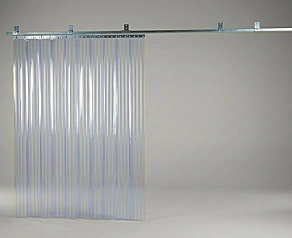

Food-industry PVC strip curtains and doors provide quick, hands-free access between food packing lines and hygienic doorways. Unlike AKON solid food-grade curtain systems, which slide side-to-side on an overhead track, strip curtain systems can be walked or driven through. This allows fast movement of staff and products while still helping to control temperature, airflow and contamination in European food processing facilities.

Update

In Europe, responsibility for ensuring that plastic compounds are suitable for food-processing environments sits with the manufacturer and the food business operator under EU and UK food-contact legislation. AKON food-grade PVC strip curtains are produced from certified raw materials intended for use in food-handling areas and supplied with appropriate documentation from our material partners. The curtains are manufactured to strict quality standards and tested to UL 94 fire performance requirements, supporting both hygiene and safety in modern food facilities.

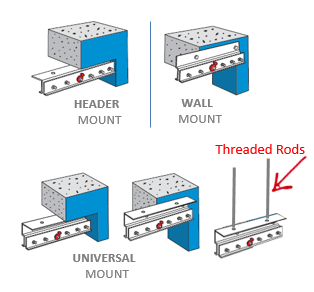

Mounting Options

Mounting Options

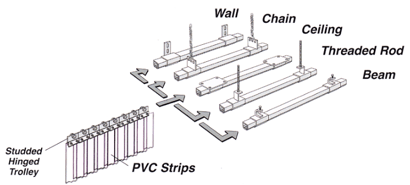

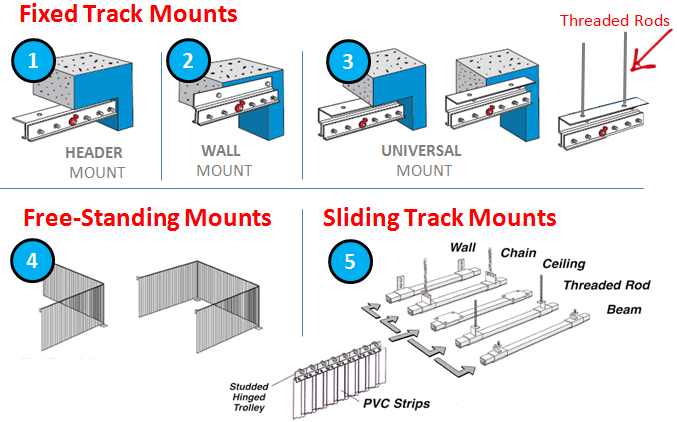

Fixed Mounts - This hardware is the most common and can mount to existing structure or be supported from above with threaded rods.

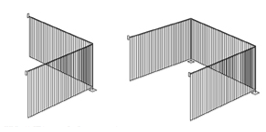

Free-Standing - If it is not possible to attach to the existing structure or hang the strips from above, you can use floor mounted hardware instead. The maximum allowed height for the freestanding style is 3.6 m.

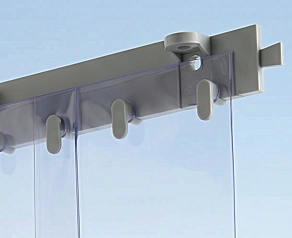

Sliding Tracks - If you have enough space, you can use rolling hardware, which allows the strips to be moved completely out of the way. Keep in mind that if you have a 3 m strip curtain, you will need 6 m of track to move it fully clear. You can also use a radius corner to create an L shape and store the food grade strip curtain off to the side.

Food Safe Strip Curtain Wall Uses

PVC Rated For USDA and CFIA Use

- UV-stabilised PVC for long-lasting clarity and durability

- Flame-retardant PVC options available

- Overlapping strips help limit spray, splashes between hygiene zones

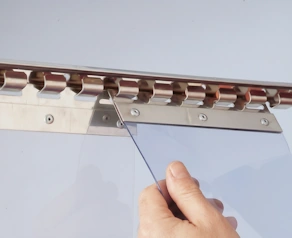

- Supplied with pre-punched strips for quick, simple installation

- Available as fixed (static) strip curtains or sliding systems for added clearance

- Individual strips are easy to unclip and replace if damaged

- Temperature food-grade PVC suitable down to approximately -30 °C

- Low-temperature freezer-grade PVC suitable down to approximately -40 °C

Common Applications

- Walk-in coolers

- Refrigeration divider walls

- Stockroom storage strip curtain walls

- Forklift traffic divider

- Food processing facility divider

- Sanitation strip curtain divider for wash down

- Clean room strip curtain partitions

Food Safe

Our Food Safe PVC Strips have been specifically designed to comply with food safety standards. Food Safe PVC is compliant with 1375/2004/CE and EU-10/2011. Food Safe PVC is recommended for the food industry, where fresh or frozen produce is present.

Features

- Food Contact Safe

- Clear - Stays clear 20% longer

- Temperature Range - Between -15 °C to 50 °C

- UV Absorber - Strips will not discolor

- Full range of fire retardant BS standards

- Crystal Clear - Extrusion Clear Processing for maximum line of sight

- Eco friendly and its 100% Phthalate Free

- High thermal insulation

- 2 Year warranty on manufacturing defects - Strips

No Phthalates

Our rolls of polyvinyl chloride strip curtains are non-phthalate and 100% recyclable! This indicates that they are safer for the environment and you to use! Additionally, our flexible PVC curtain rolls and strips offer excellent insulation, which lowers your energy costs. Additionally, they permit unrestricted traffic flow through doorways, ensuring worker safety and shielding them from the elements.

Companies That Use Food Safe Materials