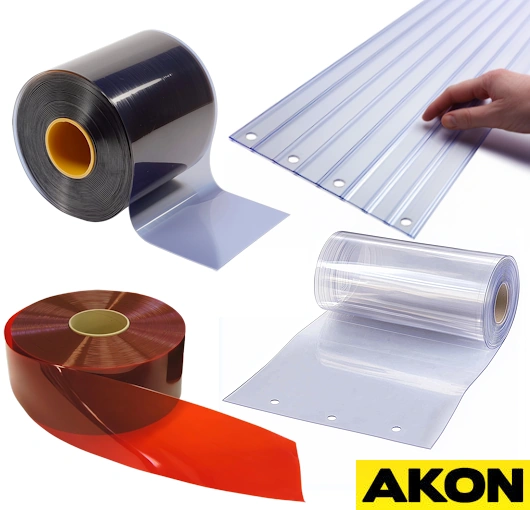

When your strips yellow, crack, or go cloudy, or you need to build new openings, PVC strip bulk rolls let you cut replacement strips on-site, pre-punch, and hang in minutes. Choose clear, ribbed, low-temp/USDA, welding tints, opaque, or anti-static grades to match your environment.Keep in mind that you can get strip door kits as well which include the hardware.

- Fast installs: Cut-to-length strips; pre-punched holes speed up hanging.

- Crystal clarity: Stabilisers deliver clearer PVC vs Ca/Zn or Ba/Zn alternatives.

- Hygiene friendly: Anti-fungal inhibitors help prevent growth/clouding.

- Any application: Standard, Low Temp/USDA, Welding, Opaque, ESD, Ribbed.

The Best PVC Bulk Rolls

Key Benifits

- Swap strips fast: Keep a roll on hand; cut/replace when needed to avoid long lead times.

- Right grade: From freezer doors (Low Temp/USDA) to welding screens (red/bronze tints) and ESD-safe areas.

Safer traffic: Clear grades with high optical clarity improve sightlines at busy openings.

- Easier upkeep: Anti-fungal, wipe-clean vinyl supports hygiene routines.

Easy Install

Replacement PVC strip bulk rolls are cut to your desired length and with pre-punched mounting holes for a quick installation.

Crystal Clear

AKON bulk PVC rolls use stabilizers which are are very clear, superior to calcium/zinc and barium/zinc stabilizers

Anti-Fungal

Anti-fungal inhibitors are used to prevent fungal growth on the surface of the PVC strips to control mold growth and clouding

Consistent Thickness

PVC is made at the proper thickness and tension to prevent strip curving as it travels from the top to the bottom of the opening

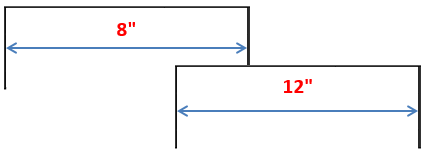

Dimensions

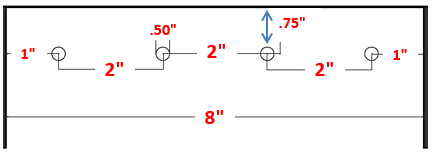

Hole Spacing

If selected, the PVC strip bulk rolls come with holes punched every 5 cm (see example of the 20 cm wide strip above). This allows the strips to fit the vast majority of strip curtain hardware on the market. You can also purchase the strips without any mounting holes. Some customers choose to punch their own mounting holes on-site. Loop style is also available for mounting to bars and tubes.

Strip Widths

PVC strip door rolls are available in widths of 10 cm, 15 cm, 20 cm, 30 cm, and 40 cm. The 20 cm wide strips are the most common and widely used. The 30 cm and 40 cm wide strips are ideal for applications with heavy motorised traffic or where the strips need to be taller than 3 m in height.

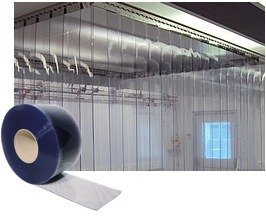

Standard Clear

USDA Low Temp

Welding

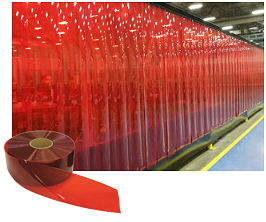

Tinted Red

Widths: 20cm, 30cm

Darkness: 2 out 4

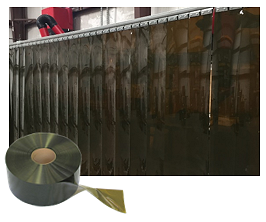

Tinted Bronze

Widths: 20cm, 30cm

Darkness: 3 out 4

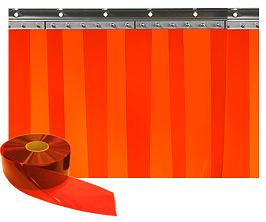

Tinted Orange

Widths: 20cm, 30cm

Darkness: 2 out 4

Tinted Blue

Widths: 20cm, 30cm

Darkness: 2 out 4

Tinted Green

Widths: 20cm, 30cm

Darkness: 4 out 4

ESD Anti-Static

Colors

Common Questions about PVC Bulk Rolls

What lengths do bulk rolls come in?

Most AKON PVC bulk rolls are supplied in long lengths (typically 45m-90m depending on grade) so you can cut strips to any opening height.

Can I pre-punch holes before hanging?

Yes—pre-punching makes installation faster and more consistent, especially when replacing multiple strips.

Which grade should I pick for freezers?

Choose Low Temp/USDA PVC—formulated to stay flexible in cold environments and common on walk-ins and freezer doors.

Do you sell welding-grade rolls?

Yes—tinted welding rolls (e.g., red/bronze) let you build compliant screens and doors directly from bulk material.

What about static-sensitive areas?

Use ESD/anti-static bulk rolls to reduce static buildup around electronics or clean environments.

Can I build sliding or stand-off strip doors from rolls?

Yes—pair the cut strips with sliding or stand-off hardware to move the opening aside or clear roll-up drums.

Order Details

- Quick Ship – Ships in 2-3 workdays!

- Lifetime Warranty on Hardware

- 5-Year Warranty on Strip Defects

- Great thermal insulators

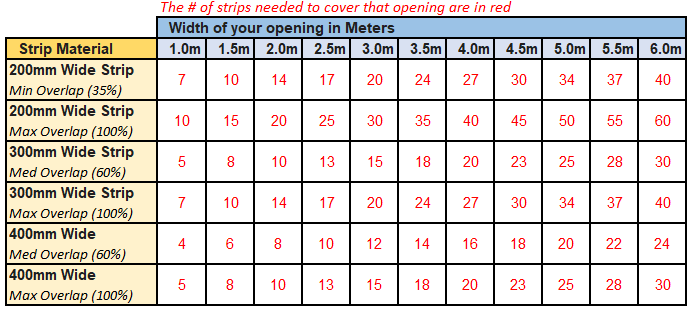

How Many Strips Do You Need?

The table below shows you how many strips you will need to cover your opening (regardless of the height). For instance, a 3.0m wide opening using 200mm strips with Minimum Overlap would need 20 strips to cover the area. If you had an 8.0m opening (which is wider than what is on this chart), you would take the requirement for a 4.0m opening x 2.

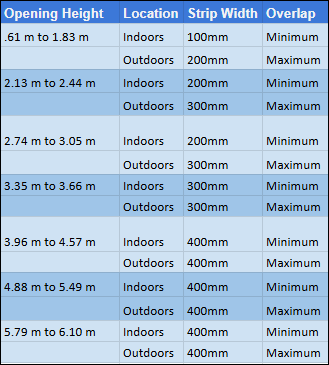

Choosing The Correct Strips and Overlap

Use this simple matrix to select the ideal strip width and overlap for your application.

Maximum overlap is about 80% to 100% strip overlap

Minimum overlap is about 40% to 56% strip overlap