Description

Details

- Lead Time - Ships in 10-12 Work Days

- Shipping - Free Shipping on orders over €150

- Vinyl Warranty - 5 Years

- 600D Warranty - 3 Years

Common Questions

Which material should I choose?

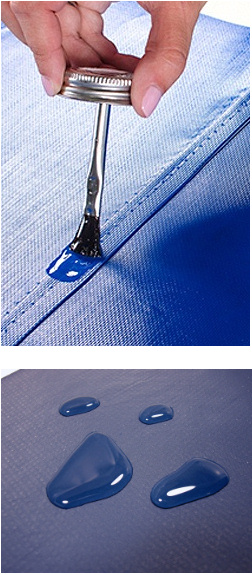

If you are trying to choose between the 18oz and 12oz vinyl materials, please choose based on your environment. For regular weather conditions, 12 oz. vinyl is a great material at a slightly less expensive price. If you are going to experience heavy weather conditions such as heavy snow, heavy rain, and lots of wind, then please choose the 18 oz. vinyl material.

What is the most common material?

The 18 ounce vinyl is used to make 90% of the covers ALCO offers. Even though both materials are equally strong and look the same, the majority of customers pick the thicker material.

Are they easy to clean?

Yes. Contrary to other polyester covers that resemble canvas, vinyl is a material that is extremely slick and is therefore simple to clean. Canvas will capture and hold mold and stains that are difficult to remove, as opposed to the sleek ALCO Vinyl custom furniture covers.

How strong are the covers?

18 oz vinyl is a very strong and long-lasting material, in fact, it is the same material that is used on the semi trailers to cover their cargo! As you can imagine, the abuse the material can endure on the highway is extreme, and if they didn't hold up, the truckers would not use them. That is why 18 oz vinyl is one of the strongest covers that you can purchase.

My cover will be used indoors. Which material is ideal?

The 600D material is the perfect material for indoors or even outdoors if its mostly in the shade and not in harsh conditions.

Common Questions

ESD Cart Covers (Antistatic) – Frequently Asked Questions

What do ESD cart covers do?

They dissipate static electricity to help protect sensitive electronics during storage and transport. AKON ESD covers also guard against dust, light moisture, and incidental impacts to keep components clean and compliant in controlled areas.

What materials are available for ESD covers?

Choose between a light-duty, static-dissipative nylon and a medium-duty 15oz vinyl with an antistatic treatment. Nylon is lightweight and flexible; vinyl adds toughness for busy corridors, staging areas, and frequent handling.

How do I measure my cart for a custom cover?

Measure width (Side A), depth (Side B), and height (Side C) in inches at the widest and tallest points, including handles or mounted bins you want covered. We add slack to all sides except height to ensure a clean fit.

Do the covers need to be grounded?

In most ESD control programs, dissipative items should have a defined path to ground. If your cart is grounded through conductive casters or a drag chain, the cover’s contact can assist dissipation. If not, request a ground tab to connect to your facility grounding point per your ESD procedures.

What surface resistivity or ESD performance should I expect?

Static-dissipative fabrics typically fall within 10^6–10^11 ohms/sq. Exact values vary by lot, humidity, and maintenance. If you need a specific range for audit purposes, let us know and we’ll confirm available options.

Are clear windows, labels, or access flaps available?

Yes. Add clear ID windows for travelers or barcodes, ESD caution labels, document sleeves, and zippered or hook-and-loop access flaps so you can retrieve parts without removing the entire cover.

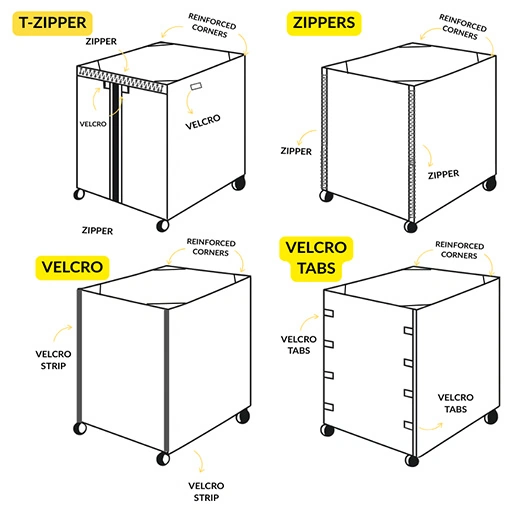

What closures and tie-down options can I choose?

Select from zippers, hook-and-loop seams, buckle straps, hem drawcords, and reinforced grommets. These features keep the cover secure during movement and help maintain cleanliness in controlled areas.

Are these suitable for cleanrooms?

Yes—our ESD nylon option is commonly used in electronics assembly, medical device, and pharma spaces. If you have specific classification or laundering requirements, share them and we’ll configure materials and construction accordingly.

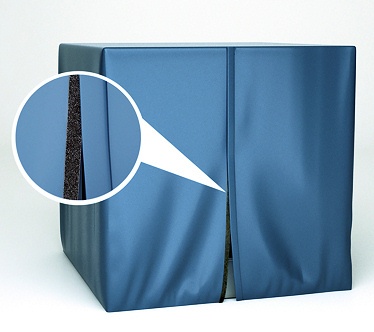

Can I get cover splits or doors for quick access?

Absolutely. We can add vertical or U-shaped splits, roll-up doors with straps, or partial openings that align with shelf heights to speed kitting and picking while keeping the cart protected.

How do I clean and maintain ESD covers?

Wipe vinyl with mild soap and water; air dry. For nylon, use a light detergent wipe or approved cleanroom wipes. Avoid harsh solvents and bleach. Regular cleaning preserves antistatic properties and audit appearance.

What colors are available?

Standard ESD sets include light forest green/black for vinyl and neutral tones for nylon. If you need color-coding for workcells or product families, ask about current availability.

What lead time and warranty do you offer?

Typical lead time is 10–12 working days after order confirmation. Vinyl covers include a 5-year warranty; nylon covers include a 3-year warranty under normal use.

How are prices determined?

Pricing depends on dimensions, material (nylon vs 15oz vinyl), features (splits, windows, zippers, ground tabs), and quantity. Larger covers and added options require more material and labor.

Can you support audits and documentation?

Yes. Upon request, we can provide material data sheets and note ESD-relevant specs to support internal documentation and audits under your facility’s ESD control program.

Do you offer bulk orders or standardized fleet builds?

Yes. We can standardize sizing, colors, labels, and access layouts across multiple cart types and offer quantity discounts for roll-outs across plants or distribution centers.